| Voir le sujet précédent :: Voir le sujet suivant |

| Auteur |

Message |

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 09/11/2008 21:59 Sujet du message: 1: 3.25 scale MG19a Steinadler Posté le: 09/11/2008 21:59 Sujet du message: 1: 3.25 scale MG19a Steinadler |

|

|

|

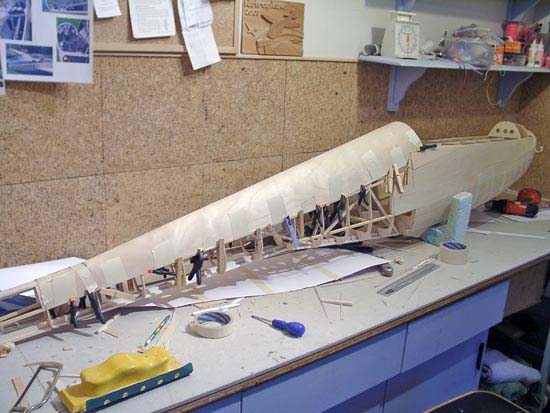

Time for a new project...!

This is a proper glider with bent wings, the MG19a...

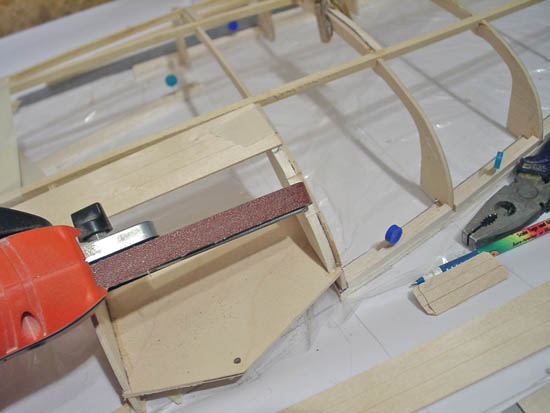

I must first of all than Vincent for letting me use his CAD drawings for reference: this has made life a lot easier. The construction will be extensively modified of course: 1: to suit my style of construction and 2: because the model will be nearly twice the size. I started cutting wood yesterday morning and,[img]

as you can see, progress has been good...

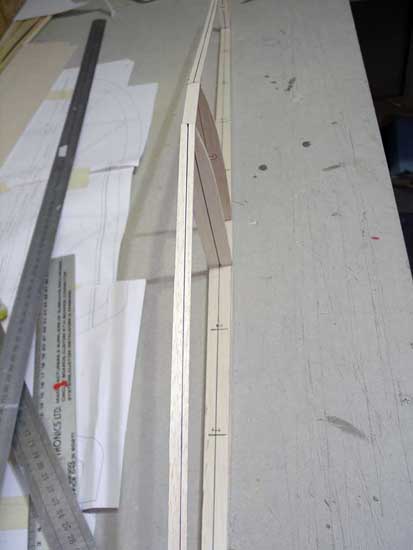

1st, a dry fit to see how it will look

Now the fuselage side is pinned to the board

Cutting the slot for the joining reinforcer between the front and rear ply sheeting

This is the joining piece, left over from the planking...

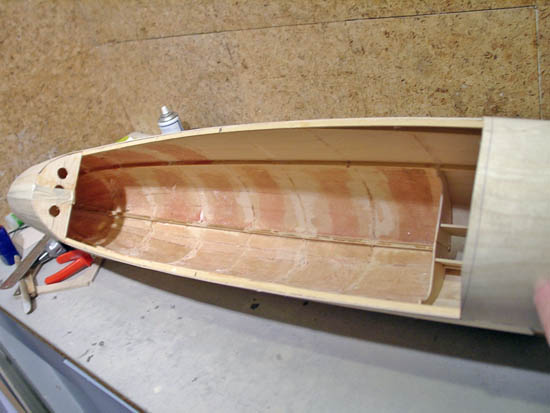

The planking contiues...

cw |

|

| Revenir en haut de page |

|

|

Orionis

Incurable Posteur

Inscrit le: 31 Aoû 2006

Localisation: Drôme

Âge: 59

|

Posté le: 10/11/2008 08:18 Sujet du message: Posté le: 10/11/2008 08:18 Sujet du message: |

|

|

|

This is another high-speed building thread!

Fabrice |

|

| Revenir en haut de page |

|

|

de Schaetzen Harold

Maniaco Posteur

Inscrit le: 06 Avr 2006

Localisation: Schilde

Âge: 80

|

Posté le: 10/11/2008 09:51 Sujet du message: Posté le: 10/11/2008 09:51 Sujet du message: |

|

|

|

Dear Chris,

Please reduce your building speed.

I need first to upgrade the speed of my PC!

Harold |

|

| Revenir en haut de page |

|

|

Paul ELLIS

Fidèle Posteur

Inscrit le: 24 Oct 2007

Localisation: Haute Vienne, Limousin

Âge: 79

|

Posté le: 10/11/2008 14:03 Sujet du message: Posté le: 10/11/2008 14:03 Sujet du message: |

|

|

|

I should have invested in masking tape and balsa when I had the chance.

Un anglais en France |

|

| Revenir en haut de page |

|

|

loopingfred

Incurable Posteur

Inscrit le: 24 Jan 2006

Localisation: Dublin - Ireland

Âge: 50

|

Posté le: 10/11/2008 16:16 Sujet du message: Posté le: 10/11/2008 16:16 Sujet du message: |

|

|

|

"Je ponce, donc j'essuie" - Rachel

MORE BEERS!!!! |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 11/11/2008 23:51 Sujet du message: Posté le: 11/11/2008 23:51 Sujet du message: |

|

|

|

It is always good to remove the fuselage half-shell from the board...

Even better to make up the other side...

cw |

|

| Revenir en haut de page |

|

|

Paul ELLIS

Fidèle Posteur

Inscrit le: 24 Oct 2007

Localisation: Haute Vienne, Limousin

Âge: 79

|

Posté le: 12/11/2008 10:32 Sujet du message: Posté le: 12/11/2008 10:32 Sujet du message: |

|

|

|

Chris

Will you be flying it at the week-end?

Vas-tu le voler ce week-end?

Paul

Un anglais en France |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 12/11/2008 23:03 Sujet du message: Posté le: 12/11/2008 23:03 Sujet du message: |

|

|

|

Paul, je ne c'est pas...peut etre il pleut...

(That's it...my only schoolboy French!)

cw |

|

| Revenir en haut de page |

|

|

Paul ELLIS

Fidèle Posteur

Inscrit le: 24 Oct 2007

Localisation: Haute Vienne, Limousin

Âge: 79

|

Posté le: 13/11/2008 09:47 Sujet du message: Posté le: 13/11/2008 09:47 Sujet du message: |

|

|

|

Félicitations Chris, tu parles bien français. ![[good]](images/smiles/good.gif)

(Trois fautes)

Un anglais en France |

|

| Revenir en haut de page |

|

|

plu ronan

Incurable Posteur

Inscrit le: 10 Jan 2007

|

Posté le: 15/11/2008 14:01 Sujet du message: Posté le: 15/11/2008 14:01 Sujet du message: |

|

|

|

tu deviens un vrai francais paul  |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 16/11/2008 16:50 Sujet du message: Posté le: 16/11/2008 16:50 Sujet du message: |

|

|

|

The planking continues...

Now the hard bit is over...!

Steaming the 1.5mm plywood for the top of the rear fuselage...

Starting to look like a proper fuselage now...

cw |

|

| Revenir en haut de page |

|

|

loopingfred

Incurable Posteur

Inscrit le: 24 Jan 2006

Localisation: Dublin - Ireland

Âge: 50

|

Posté le: 16/11/2008 17:49 Sujet du message: Posté le: 16/11/2008 17:49 Sujet du message: |

|

|

|

Hi Chris,

Quick question for you... You are using a kettle to steam the plywood.. Is it efficient with that lenght and thickness ? ![[humm]](images/smiles/humm.gif) Very good idea! One to keep for the next project ! (and handy for tea in the garage Very good idea! One to keep for the next project ! (and handy for tea in the garage  ) )

(Question pour Chris. Tu utilises une bouilloire pour former les planches a la vapeur. Est ce que c'est efficace ?)

Fred

"Je ponce, donc j'essuie" - Rachel

MORE BEERS!!!! |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 16/11/2008 17:56 Sujet du message: Posté le: 16/11/2008 17:56 Sujet du message: |

|

|

|

Fred, tea is no problem...my workshop is next to the kitchen

Steaming plywood is not very efficient, I get perhaps 25% of the shape I need, but it's enough to make trimming and glueing the ply much easier. The 6mm x 6mm Ramin longerons in the fuselage steam much better: you can get nearly all of the required shape...

La vapeur de la bouilloire avec le ctp n'est pas tres efficace, j'obtiens peut etre 25% de la forme que je veux lui faire, mais c'est assez pour le collage/découpe. les baguettes de ramin en 6x6mm se forment beaucoup plus facilement a la vapeur de la bouilloire, et il est possible de leur faire prendre toutes les formes que l'on veut...

cw |

|

| Revenir en haut de page |

|

|

loopingfred

Incurable Posteur

Inscrit le: 24 Jan 2006

Localisation: Dublin - Ireland

Âge: 50

|

Posté le: 16/11/2008 18:25 Sujet du message: Posté le: 16/11/2008 18:25 Sujet du message: |

|

|

|

Yeah, kitchen close to the garage too Yeah, kitchen close to the garage too  The builders must have been modelers ! The builders must have been modelers !

Thanks for the tip Chris ! ![[amen]](images/smiles/amen.gif)

To shape the ramin, how do you proceed ? You have a few seconds to work it out or you have a bit of time ? ![[humm]](images/smiles/humm.gif)

"Je ponce, donc j'essuie" - Rachel

MORE BEERS!!!! |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 16/11/2008 19:23 Sujet du message: Posté le: 16/11/2008 19:23 Sujet du message: |

|

|

|

Here's a photo I took earlier...

This was taken after the steaming process. Ramin is very bendy when hot and wet, so yoiu have plenty of time to get in, do the business. and then let it cool down. Gloves are a very good idea

cw |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 18/11/2008 21:51 Sujet du message: Posté le: 18/11/2008 21:51 Sujet du message: |

|

|

|

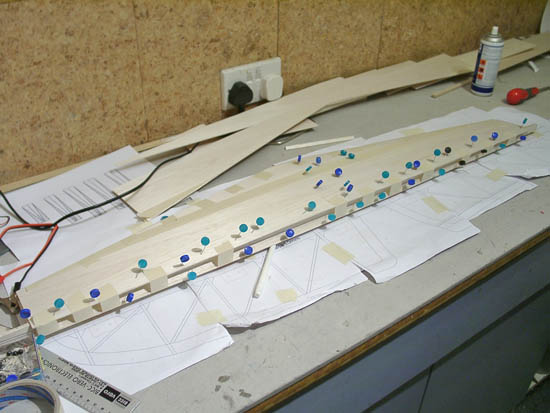

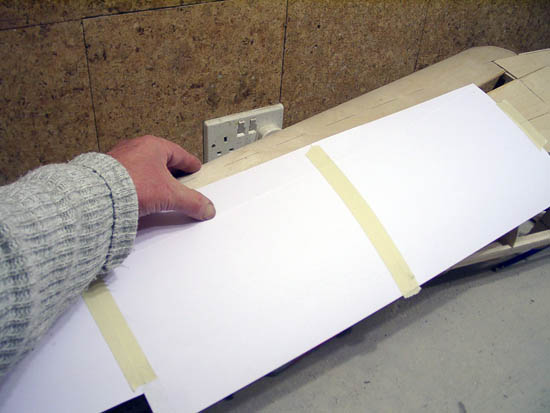

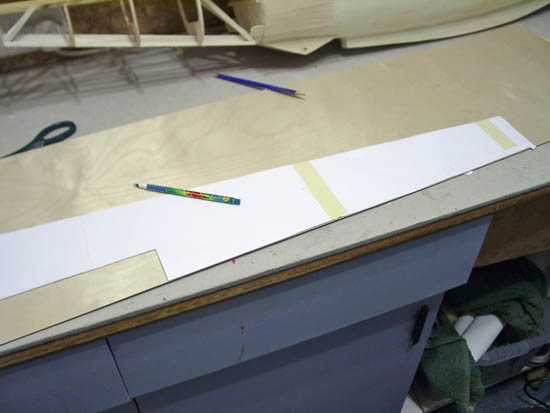

Whilst the planking of the fuselage is being completed, it's time to make a start on the stab...

Drawing centre lines on everything helps to see if it is all straight

Masking tape and pins are essential for the sheeting process (1.5mm balsa)

cw |

|

| Revenir en haut de page |

|

|

Laurent Beldame

Incurable Posteur

Inscrit le: 17 Fév 2006

Localisation: - Genève - au pied du Salève -

|

Posté le: 18/11/2008 22:37 Sujet du message: Posté le: 18/11/2008 22:37 Sujet du message: |

|

|

|

Hello Chris

An other perfect building made with frenetic rythm..The tradidional teapot is not forgotten, ramin or not ramin

L |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 20/11/2008 23:09 Sujet du message: Posté le: 20/11/2008 23:09 Sujet du message: |

|

|

|

Laurent, have you had any success with your flycam...?

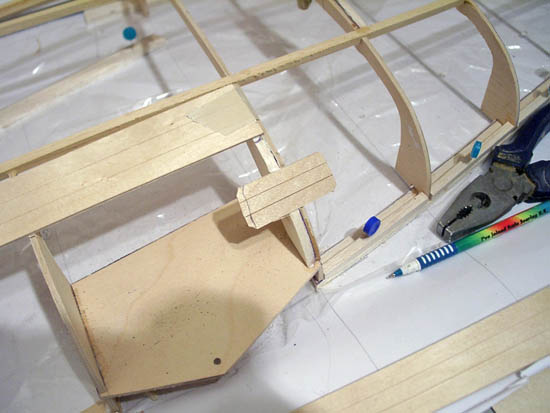

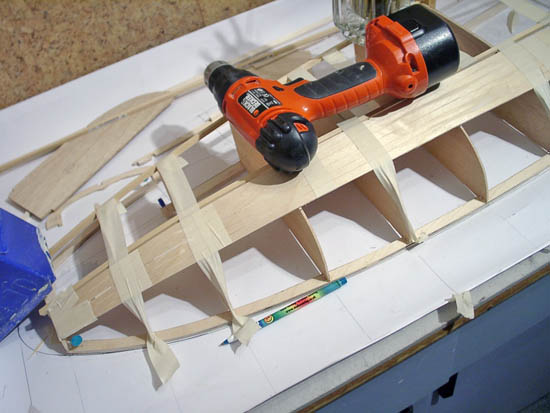

Tonight is a big night...the the temporary formers have been removed before adding the GRP

Using the power file to clean up the inside of the fuselage...

Ready now for the fibreglass

cw |

|

| Revenir en haut de page |

|

|

Paul ELLIS

Fidèle Posteur

Inscrit le: 24 Oct 2007

Localisation: Haute Vienne, Limousin

Âge: 79

|

Posté le: 20/11/2008 23:34 Sujet du message: Posté le: 20/11/2008 23:34 Sujet du message: |

|

|

|

Salut Chris

I would like a Power File like that

Je voudrais un Power File comme ça

In the UK on offer at Axminster Tools for £39.95... (€47)

En Angleterre un offre spéciale de Axminster Tools c'est €47

In France €99.99 at Mr Bricolage!!!!! (£84.69)

En France €99.99 à Mr. Bricolage!!!!

Unfortunately the postage from the UK takes it up to £55

Malheureusement avec le courier de UK c'est €65

Is there anyone here who has seen a Power File cheaper in France?

Est-ce qu'il y a quelq'un ici qui a vu un Power File moin cher en France?

Un anglais en France |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 22/11/2008 12:05 Sujet du message: Posté le: 22/11/2008 12:05 Sujet du message: |

|

|

|

Paul, I've just noticed that Machine Mart, where I bought the powerfile, have an export service...

http://www.machinemart.co.uk

+44 115 956 5555

cw |

|

| Revenir en haut de page |

|

|

Paul ELLIS

Fidèle Posteur

Inscrit le: 24 Oct 2007

Localisation: Haute Vienne, Limousin

Âge: 79

|

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 22/11/2008 18:23 Sujet du message: Posté le: 22/11/2008 18:23 Sujet du message: |

|

|

|

Before we can complete the rear of the fuselage the stab must be built.

Now it's time for the elevator...

The elevator is made over-size to be sanded back to shape later

The hinges must be supported in the stab with wooden dowel. The dowel is wrapped with masking tape first to preven splitting whilst being drilled...

Now the dowels are glued into the stab...

Once hinged up, the elevator can be sanded back flush with the stab...

Final shaping of the tips is left until the end...

Et voila, ready for the finishing touches...

cw |

|

| Revenir en haut de page |

|

|

Paul ELLIS

Fidèle Posteur

Inscrit le: 24 Oct 2007

Localisation: Haute Vienne, Limousin

Âge: 79

|

Posté le: 22/11/2008 18:38 Sujet du message: Posté le: 22/11/2008 18:38 Sujet du message: |

|

|

|

Excellent progress as usual Chris ![[clap]](images/smiles/Clap.gif)

How deep have you made the elevator shroud?

I think I made mine too deep on the Minimoa (about 12mm) hence the problems I had trying to recess the elevator deep enough.

Paul

Un anglais en France |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 23/11/2008 22:35 Sujet du message: Posté le: 23/11/2008 22:35 Sujet du message: |

|

|

|

A difficult thing to measure afterwards Paul, but I guess around 10mm

Meanwhile, the rain it rains, the wind it blows, the cold goes up your trouser legs...perfect building weather!

Time to beef up the cockpit aperture...

Now to apply the polyester filler...

As usual the nose block is made up from filler, but with some lead built in to get the ballast as far forward as possible

Now the skid has been attached...

And the cockpit aperture is now very strong...!

cw |

|

| Revenir en haut de page |

|

|

de Schaetzen Harold

Maniaco Posteur

Inscrit le: 06 Avr 2006

Localisation: Schilde

Âge: 80

|

Posté le: 24/11/2008 09:49 Sujet du message: Posté le: 24/11/2008 09:49 Sujet du message: |

|

|

|

Dear Chris,

I notice good building activiy this WE.

Now it is time to call the house keeper and specially to activate your vacuum cleaner.

Or you need to put a new breathing mask.

Best regards.

Harold |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 25/11/2008 00:29 Sujet du message: Posté le: 25/11/2008 00:29 Sujet du message: |

|

|

|

Harold, if I use our new vacuum cleaner to remove the dust, my wife will have something to say ![[oumff]](images/smiles/oumff.gif)

cw |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 28/11/2008 22:22 Sujet du message: Posté le: 28/11/2008 22:22 Sujet du message: |

|

|

|

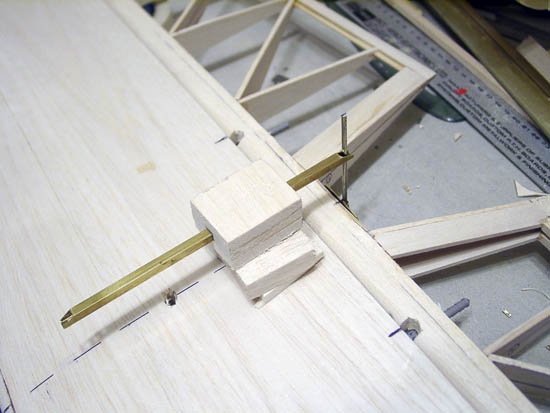

It is the weekend again, hooray...

The tailplane will be set up to rig and connect up very quickly and easily.

The 2 square brass tubes will be set in the fuselage, but first we must experiment to find the optimum set up...

Now to check it out in the fuselage...

cw |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 29/11/2008 23:45 Sujet du message: Posté le: 29/11/2008 23:45 Sujet du message: |

|

|

|

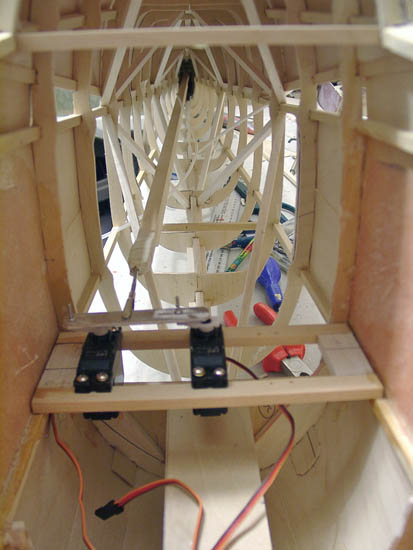

The elevator pushrod is made up from 12 x 6mm Spruce, reinforced with 6 x 10mm balsa

Two servos operate the pushrod with an aluminium connecting plate. There is a slot over one servo arm so that if one servo dies, the other can give 50% of the movement...

Another view of the pushrod in the fuselage

cw |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 30/11/2008 18:37 Sujet du message: Posté le: 30/11/2008 18:37 Sujet du message: |

|

|

|

Time now to continue sheeting the fuselage: thin card is used for a template. Pressing down with a thumb causes the edges to show up on the card to give the correct shape...

Now the shape can be transferred to the ply (CTP?)

And now the ply on to the fuselage...

cw |

|

| Revenir en haut de page |

|

|

cw

Accro Posteur

Inscrit le: 06 Juil 2008

Localisation: Blandford, Dorset, Southern England

Âge: 78

|

Posté le: 05/12/2008 23:17 Sujet du message: Posté le: 05/12/2008 23:17 Sujet du message: |

|

|

|

Work continues at the rear...meanwhile, the fuselage is now fully sheeted in CTP

cw |

|

| Revenir en haut de page |

|

|

|